Ultrafast lasers are the frontier of micromachining of a huge variety of materials including metals, semiconductors, ceramics, glasses, polymers, crystals and composites.

The intrinsic capability of tightly focused ultrashort laser pulses to modify a material with micro/nanometric precision and reduced collateral damage have disclosed new possibilities for milling, drilling, engraving, welding, cutting, surface structuring, waveguide writing, 3D printing, synthesis of novel nanocomposites.

To meet the demand of the manufacturing industry for faster processing speeds, a new generation of high power femtosecond and picosecond laser sources has been developed providing GHz repetition rates, multi-Kilowatt average powers and mJ pulse energies at different wavelengths. At the same time, faster beam steering and novel beam shaping technologies are available to exploit the full potential of such laser sources.

Our mission is to push this technology a step forward and promote its industrial use in many application fields from automotive to aerospace, medicine and diagnostics.

The research activity of our group spans from fundamental studies of light-matter interaction at extremely short time scales to the development and understanding of new ultrafast laser processes and covers (not exclusively) the following research areas:

- Advanced temporal and spatial laser beam shaping

- Laser based surface functionalization

- Laser-based fabrication of microfluidic devices

- Laser induced plasma processes and diagnostics

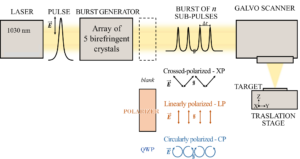

Advanced temporal and spatial laser beam shaping

Despite its undisputed precision, ultrafast lasers micromachining still suffers of long processing time. Enhancing of the efficiency is possible by tuning the laser energy in time and space. Our group works on the development and exploitation of advanced temporal and spatial laser beam shaping to deliver to the workpiece a tailored heat input by, e.g., generating bursts of ps-delayed femtosecond pulses, using non-diffractive, self-healing Bessel beams or exploiting diffractive optical element. Beam shaping thus gives the possibility to enhance the efficiency, flexibility and the precision of laser microfabrication.

Despite its undisputed precision, ultrafast lasers micromachining still suffers of long processing time. Enhancing of the efficiency is possible by tuning the laser energy in time and space. Our group works on the development and exploitation of advanced temporal and spatial laser beam shaping to deliver to the workpiece a tailored heat input by, e.g., generating bursts of ps-delayed femtosecond pulses, using non-diffractive, self-healing Bessel beams or exploiting diffractive optical element. Beam shaping thus gives the possibility to enhance the efficiency, flexibility and the precision of laser microfabrication.

Laser based surface functionalization

Throughout the evolution, nature has been able to adapt to the environment, creating materials with unique properties, typically related to their surface morphology. Ultrafast laser-based technology is particularly suitable to generate very reproducible and precise micro- and nanostructures on a wide range of materials. Taking inspiration from nature, our groups exploits laser surface texturing to structure materials surfaces on the micro- and nanometer scale to confer them novel and augmented properties and new functionalities, such as anti-wear, friction and drag reduction, controlled wettability (superhydrophilicity/superhydrophobicity) for anti-fogging, water capture and anti-icing, smart adhesiveness, tailored optical properties, increased emissivity.

Throughout the evolution, nature has been able to adapt to the environment, creating materials with unique properties, typically related to their surface morphology. Ultrafast laser-based technology is particularly suitable to generate very reproducible and precise micro- and nanostructures on a wide range of materials. Taking inspiration from nature, our groups exploits laser surface texturing to structure materials surfaces on the micro- and nanometer scale to confer them novel and augmented properties and new functionalities, such as anti-wear, friction and drag reduction, controlled wettability (superhydrophilicity/superhydrophobicity) for anti-fogging, water capture and anti-icing, smart adhesiveness, tailored optical properties, increased emissivity.

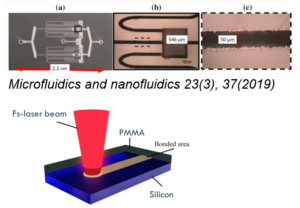

Laser-based fabrication of microfluidic devices

Our group develops advanced fs-laser based fabrication solutions for rapid prototyping of polymeric microfluidic devices, with high degrees of precision and flexibility, from the design (CAD) to the proof-of concept application. The fabrication procedures are mainly based on fs-laser micromachining technique also possibly combined with other techniques, without the need for the expensive masks and complex facilities. The lab-on-a-chip (LoC) devices are mainly realized in polymethyl methacrylate (PMMA), a low cost and biocompatible material, joined to other polymers, metals or silicon. The power of miniaturization of fs-laser technology is exploited to create revolutionary microfluidic lab-on-chip devices uniquely suited to sense and manipulate particles, allowing us to solve current problems in health and medicine.

Our group develops advanced fs-laser based fabrication solutions for rapid prototyping of polymeric microfluidic devices, with high degrees of precision and flexibility, from the design (CAD) to the proof-of concept application. The fabrication procedures are mainly based on fs-laser micromachining technique also possibly combined with other techniques, without the need for the expensive masks and complex facilities. The lab-on-a-chip (LoC) devices are mainly realized in polymethyl methacrylate (PMMA), a low cost and biocompatible material, joined to other polymers, metals or silicon. The power of miniaturization of fs-laser technology is exploited to create revolutionary microfluidic lab-on-chip devices uniquely suited to sense and manipulate particles, allowing us to solve current problems in health and medicine.

Laser induced plasma processes and diagnostics

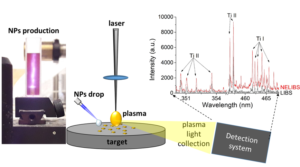

The studies on the fundamental processes of Laser-Induced Plasma (LIP) dynamics in different environments (gases and liquids at different pressures) have been successfully applied to the most common applications related to LIP-based spectroscopy and spectrometry as well as to industrial processes and production of nanostructures. We perform: 1) Spectroscopic diagnostics of LIP processes; 2) Chemical analysis with Laser Induced Breakdown Spectroscopy (LIBS) (volcanic powders, archaeological findings, meteorites, gemstones, soils and plants, samples submerged in water, etc.); 3) Nanoparticles and nanostructures production by Pulsed Laser Ablation in Liquids (PLAL) and their employment in different fields (analytical chemistry, biochemistry); 4) Study of the interaction of naked NPs produced by PLAL with biological systems (i.e. human ubiquitin, human serum albumin (HSA), human cells, specific antibodies etc.); 5) Applications of NP field enhancement effects through the Nanoparticles Enhanced Laser Induced Breakdown Spectroscopy (NE-LIBS) technique (chemical analysis at sub-ppm level).

The studies on the fundamental processes of Laser-Induced Plasma (LIP) dynamics in different environments (gases and liquids at different pressures) have been successfully applied to the most common applications related to LIP-based spectroscopy and spectrometry as well as to industrial processes and production of nanostructures. We perform: 1) Spectroscopic diagnostics of LIP processes; 2) Chemical analysis with Laser Induced Breakdown Spectroscopy (LIBS) (volcanic powders, archaeological findings, meteorites, gemstones, soils and plants, samples submerged in water, etc.); 3) Nanoparticles and nanostructures production by Pulsed Laser Ablation in Liquids (PLAL) and their employment in different fields (analytical chemistry, biochemistry); 4) Study of the interaction of naked NPs produced by PLAL with biological systems (i.e. human ubiquitin, human serum albumin (HSA), human cells, specific antibodies etc.); 5) Applications of NP field enhancement effects through the Nanoparticles Enhanced Laser Induced Breakdown Spectroscopy (NE-LIBS) technique (chemical analysis at sub-ppm level).